|

|

Ultrasonic testing equipment Digital ultrasonic flaw detector Ultrasound flaw detector RFD820

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Ultrasonic Testing Equipment Digital Ultrasonic Flaw Detector Ultrasound Flaw Detector RFD820 | Measuring Range(mm): | 0 ~ 15000 |

|---|---|---|---|

| Pulse Repetition Frequency: | 20-3000Hz | Units: | Inch Or Millimeter |

| Sensitivity: | 120 DB Max | Dynamic Range: | ≥38dB |

Ultrasonic testing equipment Digital ultrasonic flaw detector Ultrasound flaw detector RFD820

![]()

User friendly dialog interactive helps operations like Calibration, making curves, etc.

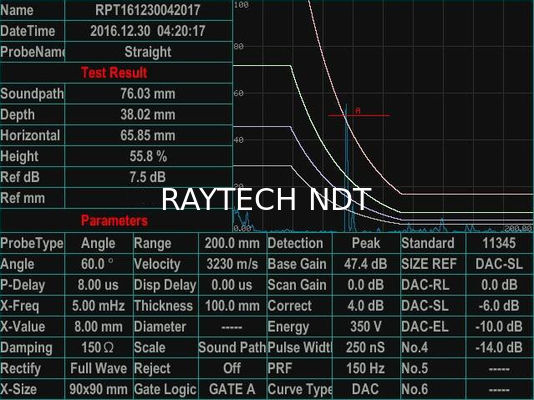

★ All tools you need: DAC, AVG, TCG,color Bscan, AWS, Spheroidization Rate, etc.

★ Pulse Repeatition Frequency: 20-3000Hz precise adjust, high speed scan, no miss out.

★ High Signal to noise ratio, clear and stable echo, anti-noise design, perfect for tough working conditions.

★ 12-digit AD, high speed sampling leads to better echo diagram with all details. Sensitive and can detect even tiny flaws.

★ Can use probe frequency 30M perfectly .

★ High speed real-time flaw detection video recording. Unlimited USB data storage.

★ Blue tooth connection to mobile device to generate and print detection reports on-site.

★ IP65 standard. Alloy + Silica gel case, water and dust proof, solid and lasts forever. Damping support makes it stands in any angle.

★ Battery lasts 15 hours for one charge. Each battery has own charging control so with two batteries it can work around the clock.

Specifications

Range:0-15000 mm ,at steel velocity

Material Velocity:100~20000 m/s

Pulse Repetition Frequency:20-3000Hz

Dynamic range:≥38dB

Linearity: Horizontal: +/-0.2%, Vertical: 2.5%, Amplifier Accuracy +/-1 dB.

Resolving Power:>40dB (5P14)

Sensitivity Leavings:>62dB

Reject (suppression): 0 to 80% full screen height

500 independence setup, any criterion can be input freely, we can work in the scene without test block;

Big memory of 1000 A graph

Test Modes: Pulse echo, dual element and thru-transmission

Probe Types: Single Straight, Single Angle,Daul Straight, Daul Anlge,Thrugh,Creeping,Surface

Gate Monitors: Two independent gates controllable over entire sweep range

Units: Inch or millimeter

Power Requirements: AC Mains 100-240 VAC, 50-60 Hz

Display Delay: -20 to 3400 µs

Probe Delay/Zero Offset : 0 to 99.99µs

Internal rechargeable Li-ion battery pack rated 7.2V at 8000 mAh

15 hours nominal operating time depending on display brightness

4 hours typical recharge time

H×W×D(mm):260×175×60 (mm)

Weight :1.2kg

Operating Temperature: -10℃ to 50℃

Storage Temperature: -30℃ to 50℃

Pulse Energy: 70V,100V,200V, 300V, 400V, 500V selectable

Rectification: Positive half wave, negative half wave, full wave, RF System

Bandwidth (amplifier bandpass ): 0.2 to 35 MHz

Gate Monitors: Two independent gates controllable over entire sweep range

Sensitivity: 120 dB max in selectable resolution 0.1, 1.0, 2.0, 6.0 dB.

Transducer Connections: BNC or LEMO

Functions

Automated display precise flaw location(Depth d,level p,distance s,amplitude,sz dB,ф).

Flaw sizing: Automatic flaw sizing using AVG or DAC/TCG, speeds reporting of defect acceptance or rejection.

Automated calibration of transducer Zero-point, Angles, Front edge and material Velocity . ( V2 and two hole )

Convenient to make and use DAC/TCG and AVG to evaluate the echo, the curve can be modified and compensated.

Connectting U-Disk,the unit can get unlimited memory.

Automated make video of test process and play; use upan,the length of video is unlimited.

Color Bscan.

There are 17 standards of in the unit.

Blue tooth connection to mobile device to generate and print detection reports on-site. AWS D1.1.

Curved Surface Correction feature.

Crack Height Measure function.

Magnify gate:spreading of the gate range over the entire screen width.

Auto-gain function.

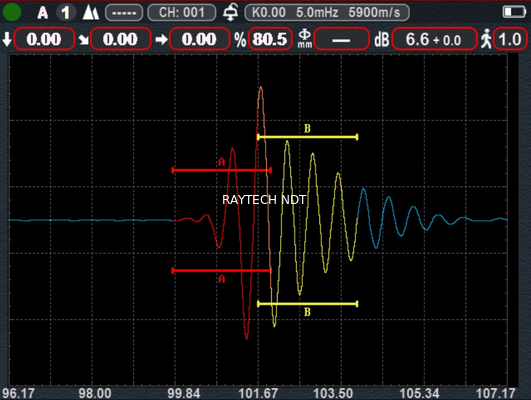

Envelope: Simultaneous display of live A-scan at 70 Hz update rate and envelope of A-scan

display.

Peak Hold: Compare frozen peak waveforms to live A-Scans to easily interpret test results.

Scan Freeze:Display freeze holds waveform and sound path data.

Spheroidization Rate test.

Alarm:Beep and LED.

Real Time Clock.

Fill echo.

Capture mark.

Echo color within the Gate.

Standard Configuration

|

|

Name | QTY |

| 1 | Main unit | 1 |

| 2 | power adaptor | 1 |

| 3 | probe connecting cable | 2 |

| 4 | Instrument case | 1 |

| 5 | Instruction manual | 1 |

| 6 |

Straight probe |

1 |

| 7 | Angle probe 8x9 60°4MHz | 1 |

| 8 | Certificate of approval | 1 |

| 9 | Strap | 1 |

| 10 | App Software | 1 |

![]()

TAG: Ultrasonic flaw detector Digital ultrasonic flaw detector Flaw Detector Ultrasonic

-

UT flaw detector Ultrasonic ndt equipment Digital ultrasonic flaw detector RFD620

-

Wireless Connection Ultrasonic Flaw Detector metal flaw detector

-

UT Transducer, Ultrasonic flaw detector probe, Straight Probe, Angle Beam, Dual element

-

Taper Gage, HI-LO Welding Gauge, AWS Gauge, Fan Shape Gauges, Ultrasonic Flaw Detector

-

Ultrasonic Transducer, Ultrasonic Probe, Ultrasonic flaw detector probe, Ultrasonic fault detector probe

-

Pipe pit gage, Digital welding gage, Welding seam gauge, Inspection mirror, Ultrasonic Flaw Detector